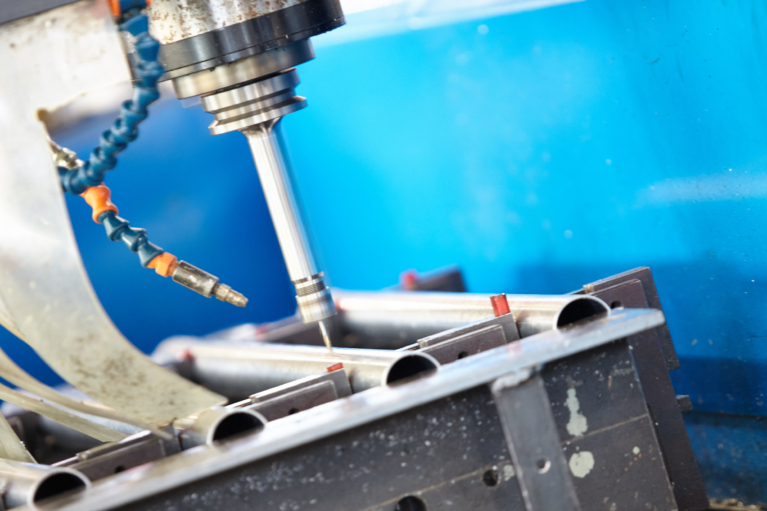

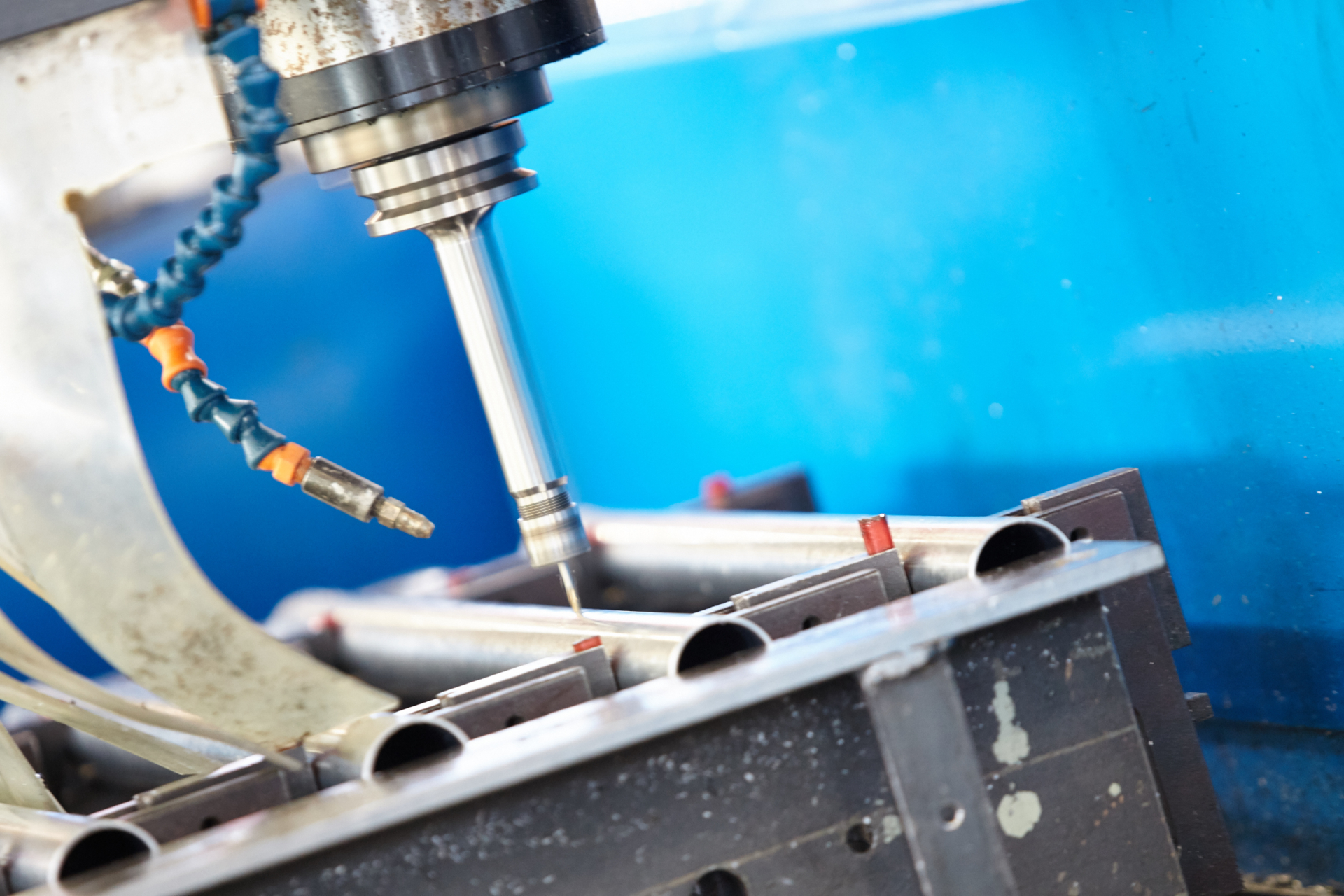

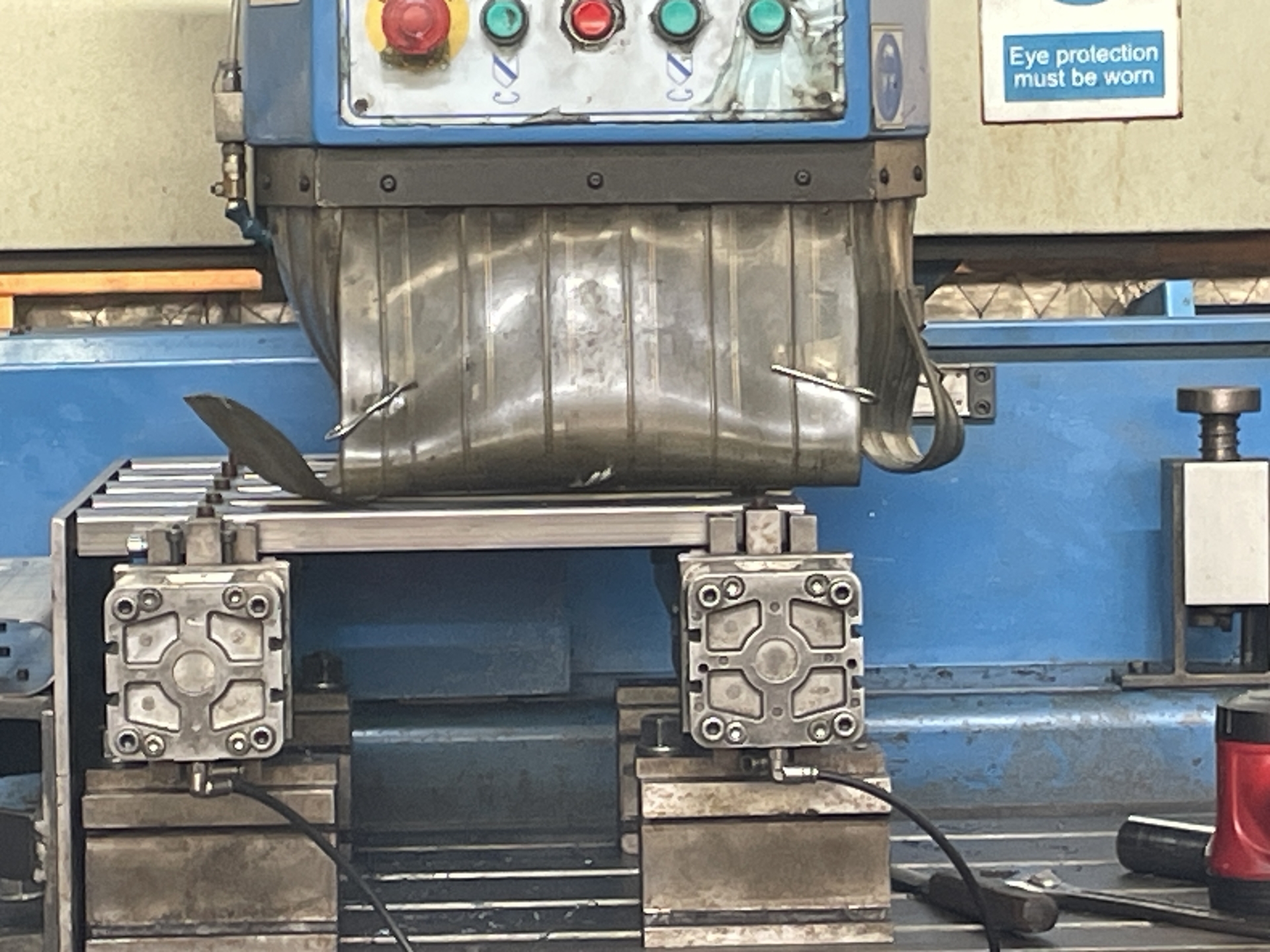

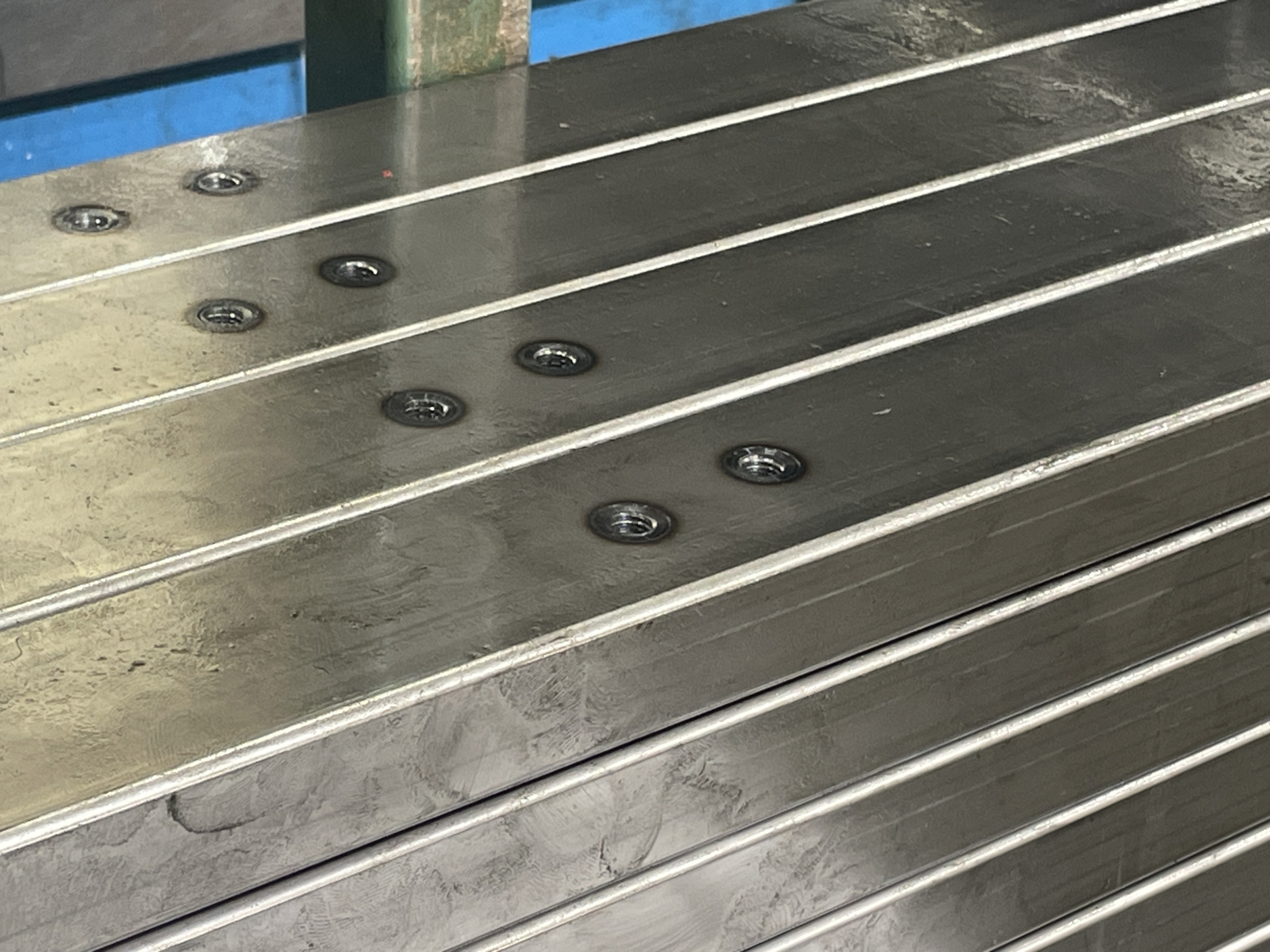

CNC drilling

CNC drilling is the perfect solution for tubular products requiring multiple precision holes, flow drilling and tapping.

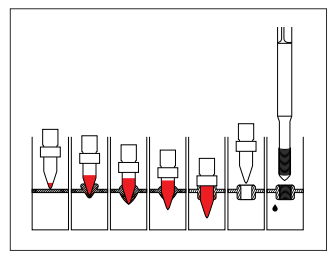

- Flow drilling (or thermal/friction drilling) is often used as an alternative to rivet nuts, creating tapped holes for bolts and screws in product assembly.